Our Recent Customer Visits Across the UK

There’s nothing quite like getting out to see customers face-to-face. Over the past month, the ALPHR team has been travelling across the UK, catching up with some familiar faces and meeting new ones too. These visits are a chance to hear what’s going on in their world, find out where they might be facing challenges, […]

Meet the Team: Norbert Palenstijn

Norbert Palenstijn wears quite a few hats. As ALPHR’s US Brand Manager, he also represents our sister companies Nolek, who specialise in leak testing and detection, and Natgraph, experts in drying and curing systems. It’s a role that keeps him right at the intersection of technology, industry, and customer needs and that’s exactly where he […]

Meet the Team: Mark Timson

With a solid background in sales engineering and a strong grasp of the technical nitty-gritty, Mark’s role at ALPHR is all about connection, connecting customer challenges with solutions that actually work, not just on paper, but in the real world of smart manufacturing and automation. He’s the kind of guy who thrives on clarity. When […]

A Look at Our Latest R&D Work

R&D continues to be a big focus for us here at ALPHR. Every project we work on presents different challenges, and we’re always looking for better, smarter ways to solve them. Whether it’s developing new hardware, trialling improved software, or exploring ways to simplify integration, our engineering team has been pushing forward on several fronts […]

Checking In with Our Key Suppliers

It’s been a busy few weeks at ALPHR, and we’ve had the chance to sit down with some of our key suppliers to talk through ongoing projects, explore new ideas, and look at how we can improve the way we work. Here’s a quick round-up of what we’ve been up to. Looking at Logistics One […]

Seeing Automation in Action

Over the past few weeks, we’ve had the opportunity to spend time with some of our customers, including Harting UK, Kautex Unipart, Bifrangi UK, and Mitsubishi. Seeing their operations up close gave us fresh insight into the way manufacturers are adapting to current challenges. One thing was clear across every visit. Automation is being used […]

Why Test & Measurement Matters More Than Ever

In any production environment, it’s not just about making things, it’s about making sure they work, every time. Even the most well-designed product can cause problems if it hasn’t been properly tested. That’s why test and measurement plays such an essential role. At ALPHR, we’ve spent over three decades working with manufacturers to make sure […]

What Happens After Your ALPHR Machine Arrives?

At ALPHR, we don’t just build machines; we build real partnerships. Whether you’ve just received a brand-new system or you’ve got equipment that’s been humming along for years, we truly believe that ongoing support is just as vital as the solution itself. Lately, members of our team have been out and about, working closely with […]

Catching Up with Our Suppliers at ALPHR

We’ve recently had the pleasure of opening our doors and welcoming some of our most important suppliers here at ALPHR. These visits are always fantastic opportunities to really strengthen our relationships, get hands-on with exciting new tech, and have the kind of frank, productive conversations you just can’t get over email. Festo Rolls In with […]

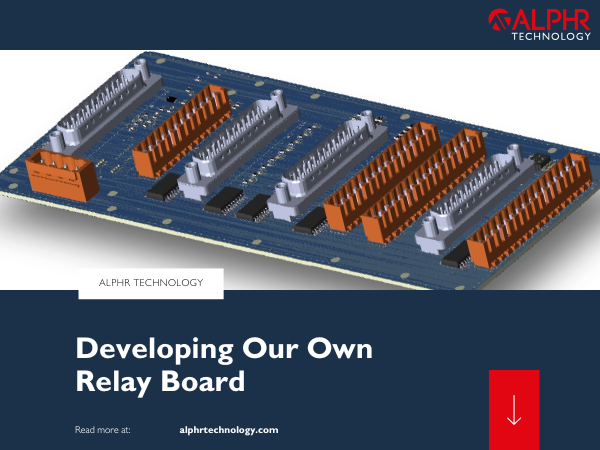

Developing Our Own Relay Board

Our R&D team is always looking for ways to improve how we design and build automation systems. We’ve just kicked off a new internal project which involves developing our very own relay switching board. This board will be built in-house and is designed to handle over 40 inputs and outputs. It will be controllable via […]