ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

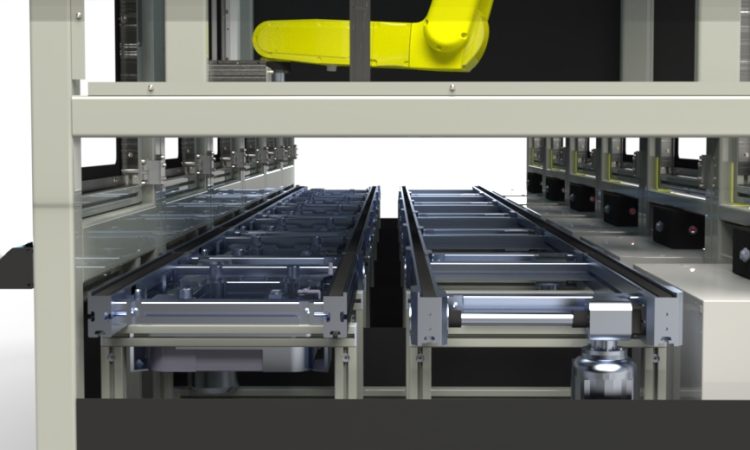

Palletised & Automated Assembly Lines

Palletised & Automated Assembly Lines

We can confidently say that we are one of only a few companies that specialise in palletised assembly lines. Many of our clients have assembled and tested their products on ALPHR’s palletised systems. This has allowed us to gain considerable knowledge and experience in this field.

Palletised lines provide the perfect solution when multiple controlled assembly and test processes are required and the product needs to be retained within the production line, reducing WIP. Palletised systems allow for multiple processes to be incorporated into a single multi-stage production line, whether semi or fully automated.

Bespoke Palletised Systems

Our experience allows us to incorporate multiple palletised assembly cells, arranged around a palletised transfer system, allowing for continuous, fully controlled assembly and testing with minimum operator input.

Some of the processes our palletised systems have incorporated include:

Poka-yoke assembly

Vision inspection

Robotised pick & place

Robotised screwdriving

Robotised dispensing

Display testing

Automated label print and apply

The above list is by no means exhaustive and reflects the versatility and flexibility of a palletised assembly and test line.

Taking all the experience we have gained in palletised assembly and testing, and coupling this with our in-depth robotics knowledge, we have been able to develop a standard range of palletised robotic systems that seamlessly integrate with non-robot cells on a bespoke production line. ALPHR Technology is able to provide clients with images, visualisations and cycle timings of a line during the requirement capture phase of a project, mitigating any perceived risk associated with automation.

ALPHR’s standard palletised offering results in reduced lead times and lower costs, resulting in a quicker return on investment, earlier than traditionally would be expected.

Benefits include:

Reduction in human error

Reduction of WIP

Fully controlled end-to-end assembly process

Multiple processes carried out on one production line

Parallel processing

Ease of maintenance and service

Designed for reliability, availability, maintainability and safety (RAMS)

Multiple product variants can be accommodated

Flexible and modular solution, allowing additional stations to be easily added

Reduced operator input

Reduced product handling

End-to-end product traceability