Menu

Menu

Menu

ALPHR UK

Amor Way, Dunhams Lane,

Letchworth, Hertfordshire, SG6 1UG

Letchworth, Hertfordshire, SG6 1UG

Home » Advanced Automation Systems » Ultrasonic Welding Solutions

Need more information, or thinking about working with us?

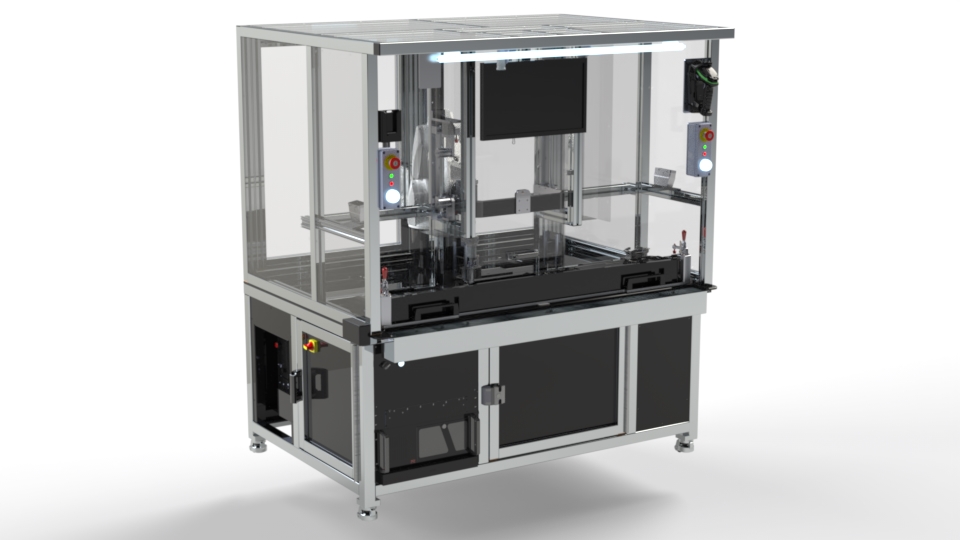

Ultrasonic Welding Solutions

Welding Solutions

As well as offering solutions for more traditional assembly and jointing techniques, ALPHR Technology can offer the integration of an ultrasonic welding machine for the joining of a range of polymers into its bespoke automated assembly and test solutions.

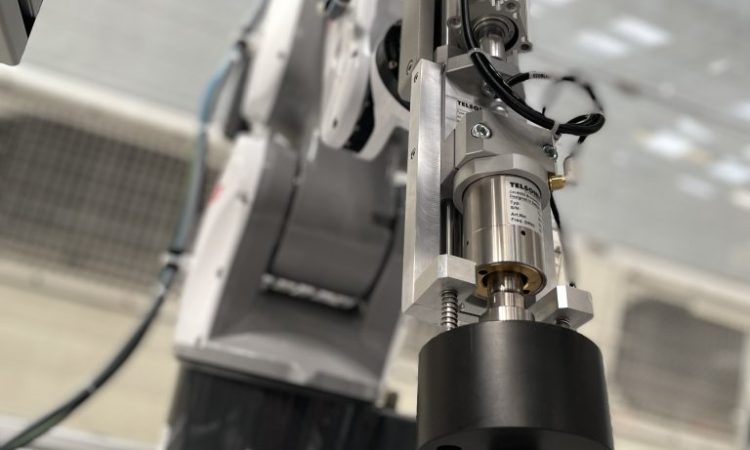

Working in collaboration with industry-leading manufacturers of ultrasonic welding systems, such as Branson and Telsonic, we ensure the right hardware is deployed for your project.

The advantages of ultrasonic welding include:

Weld quality – creates a clean and sanitary joint with a hermetic seal

Durability – parts joined on a molecular level

Reduced production costs – no additional fillers, adhesives or fasteners required

Fast cycle times – no drying or during time required

Ease of integration – an ultrasonic metal welding machine can be integrated into manual, semi-automatic, and fully automatic systems

Low thermal impact on materials – no thermal distortion created

Ultrasonic Welding Applications

Ultrasonic welding applications include:

Consumer goods

Electronics

Packaging

ALPHR Technology follows a number of fundamental design criteria for achieving a strong molecular bond between the two polymer sections to be joined, and is able to create a fixturing solution to engage with the welding system sonotrode. This results in excellent weld-to-weld uniformity and minimal scrap rates due to the highly repeatable nature of this welding process.

For more information about how ALPHR Technology can incorporate ultrasonic welding technology into your assembly process, get in touch with us today. Talk to one of our highly experienced engineers who will be happy to answer your query. Our solutions are available to clients in the UK and worldwide.