ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

Laser Marking Machines

Marking

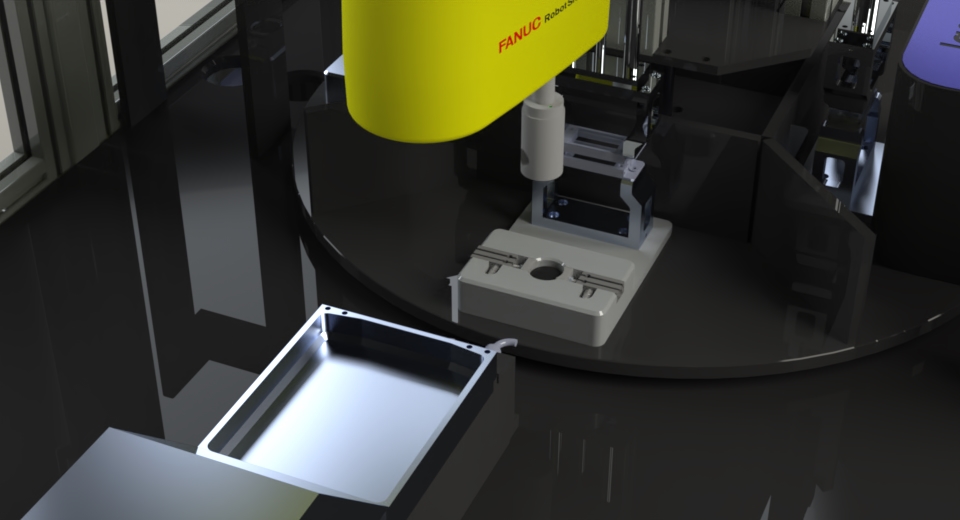

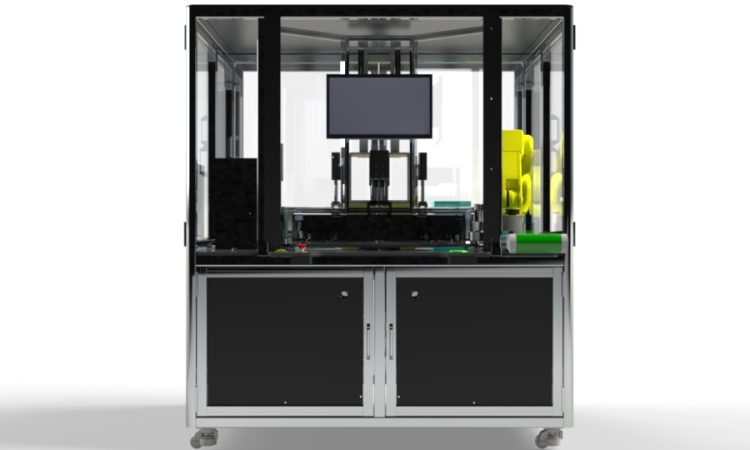

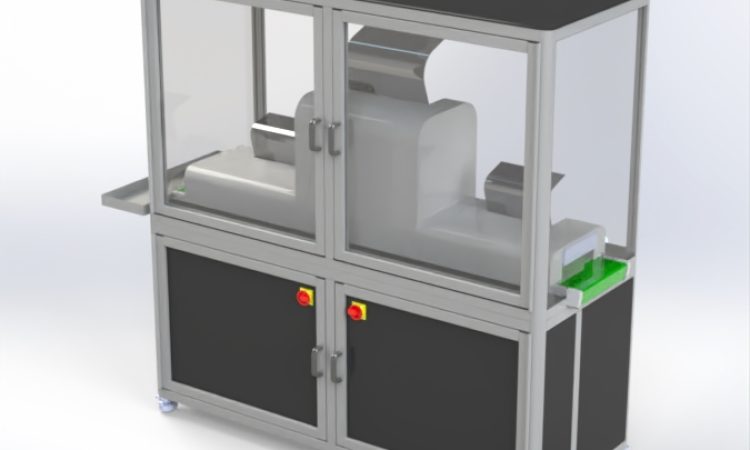

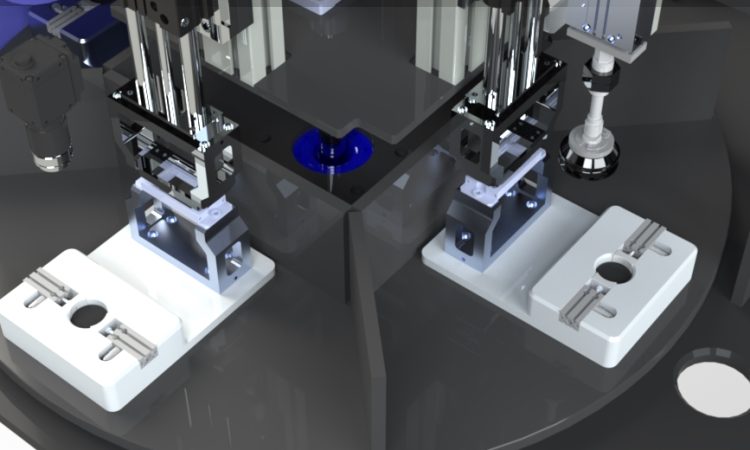

ALPHR Technology are experts in automated solutions which require part-marking as part of the manufacturing process. ALPHR has integrated systems from leading OEMs in the following marking techniques:

Laser marking

Label printing

Print & apply

Tampa printing

Automated loading and unloading of parts

Barcode printing and reading

2D datamatrix and QR code printing and reading

RFID (read/write)

The Benefits of Laser Marking

Over the last few years, laser marking machines have grown in popularity due to their increased accessibility to new users. Laser marking is a clean, quick solution to part marking, and it generates very little noise compared to traditional engraving systems.

Further benefits to laser marking include clear markings of alphanumeric, 1D and 2D barcodes and graphics, minimal maintenance, consistent code legibility, reduced operating costs and easily programmable for changes and future variants.

ALPHR has supplied a wide range of automation solutions that integrate marking into the production process. Covering a multitude of products including polymers, metals, PCB’s and cardboard, it is our experience in this technology that ensures that all safety regulations and technical aspects are fully considered.

By combining part marking with real time data collection, exceptional levels of traceability can be achieved. Barcodes, data matrixes and even text can be marked, read and gauged using a wide range of products, allowing manufacturing and test data to be stored against a specific part/model number. Technology has allowed ALPHR to develop robust traceability systems that offer potential cost savings by reducing warranty claims and product recalls, but also improving quality and efficiency.