ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

Automated Leak Detection Systems

Automated Leak Detection

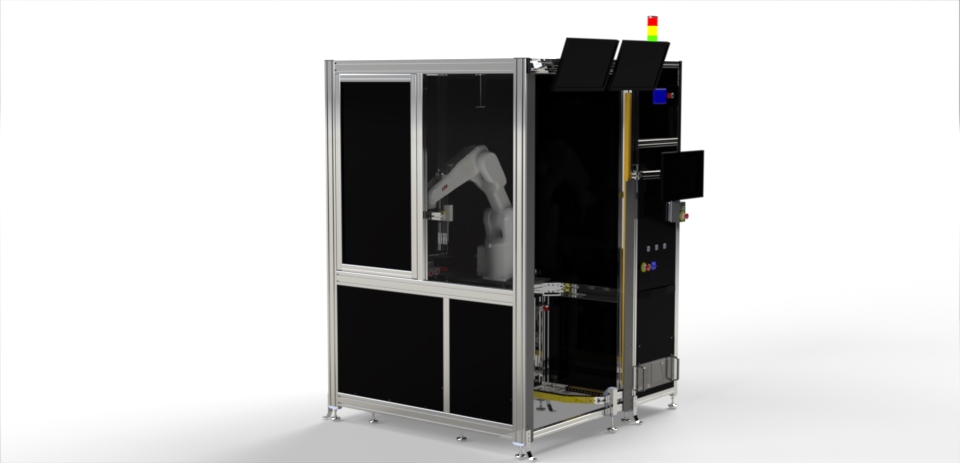

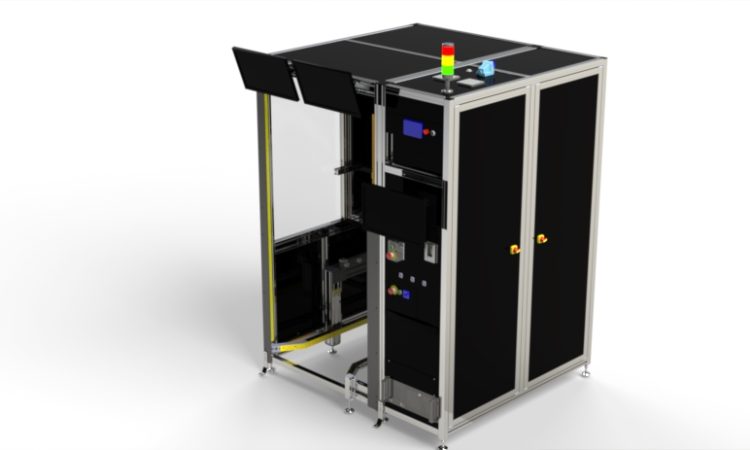

At ALPHR Technology, we design and build bespoke pressure decay leak detection test machines. We integrate the most appropriate technology from industry-leading OEMs to provide high-accuracy measurements with the associated improvements to accuracy.

With 30 years of experience to call on, we have provided systems to clients in multiple sectors, including Automotive, Medical, HVAC, and Defence.

Collaborative Leak Detection Equipment

Injection molded parts

Castings

Headlights

Inhalers

Solenoids

Valves

Brakes systems

Fuel systems

Fuel pumps

Oil pumps

Syringes

Domestic boilers & white goods

HVAC systems

Please do contact us to find out more about how ALPHR can help. Our pressure decay test equipment is available to clients in the UK and worldwide.

Frequently Asked Questions

What is automated leak detection?

Automated leak detection is the process of using machines and sensors to identify leaks in components or systems without manual inspection. Our systems use pressure decay testing, which measures pressure changes over time to detect even the smallest leaks with precision.

How does pressure decay leak detection work?

Pressure decay testing works by pressurising a sealed part, then isolating it and monitoring the pressure over a set period. A drop in pressure indicates a leak. It’s a reliable, non-destructive method used widely in automotive, medical, and industrial applications.

What are the benefits of automated leak detection?

- Higher Accuracy: Detects micro-leaks with minimal false positives

- Repeatability: Consistent results across every test cycle

- Improved Safety: Reduces operator handling of hazardous or sensitive components

- Faster Testing: Increases throughput in production environments

- Data Logging: Supports traceability and compliance

- Lower Costs: Reduces rework, product recalls, and quality failures

What industries use ALPHR’s automated leak detection systems?

Our solutions are used across:

- Automotive: Brakes, fuel systems, oil pumps, headlights

- Medical: Inhalers, syringes, sealed enclosures

- HVAC & White Goods: Boilers, valves, heat exchangers

- Defence & Industrial Manufacturing: Castings, solenoids, mission-critical components

Can automated leak detection be integrated into existing lines?

Yes. ALPHR offers modular systems that can be installed as standalone test stations or fully integrated into rotary tables, palletised lines, or robotic cells. Systems are available in manual, semi-automated, or fully automated configurations depending on your needs.