Every manufacturer has been there. The line is running smoothly, production targets are being met, and everything seems on track. Then, a few days later, a call comes in. A batch has failed quality control. A small fault that slipped through unnoticed during inspection has caused a delay, a recall, or worse, a frustrated customer.

It is a familiar story. The truth is that human inspection, while valuable, can only go so far. Even the best-trained eyes miss things. Fatigue, repetition, and the sheer pace of production make it impossible to catch every defect. This is where vision inspection quietly steps in as one of the most reliable problem solvers on the factory floor.

At ALPHR, we have seen first-hand how automated vision inspection transforms production lines. It is not flashy or dramatic, but its impact is enormous. It improves quality, consistency, and confidence, all while reducing waste and saving time. It is the kind of technology that once you have it, you wonder how you ever managed without it.

The moment everything changed

Imagine you are producing an automotive component with several small connectors. Inside one of those connectors, a terminal is slightly bent, a fault that is almost impossible to spot during manual inspection. The connector housing itself may still appear aligned and may even allow the mating connector to engage, but the bent terminal prevents proper electrical contact. The part passes manual inspection, gets shipped out, and then fails to mate during final assembly, resulting in a quality claim from the car maker. The cost and time involved in identifying, tracing, and correcting that issue can be eye-watering.

Now imagine that same part going through a vision inspection system. Within milliseconds, the camera detects the bent terminal, flags the part, and stops it from moving further down the line. The problem is caught at the source, before it ever becomes a headache. That single moment of prevention saves hours, maybe days, of lost production time.

This is what vision inspection does best. It removes uncertainty. It allows manufacturers to find errors early and fix them quickly, turning potential disasters into simple adjustments.

More than just a camera

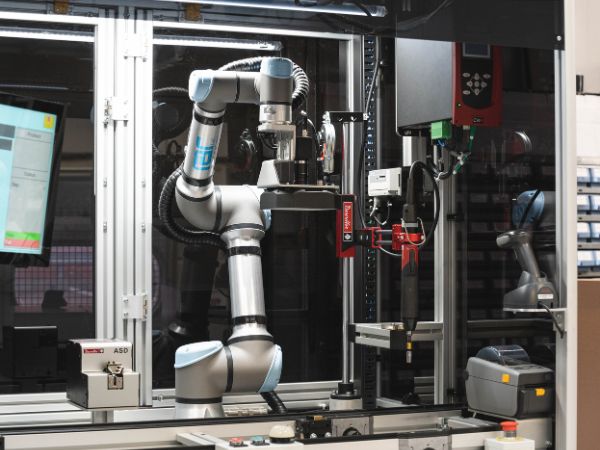

There is a common misconception that vision inspection is just about cameras taking pictures. In reality, it is a complete system that combines optical precision with intelligent software. Lighting, positioning, and image processing all work together to identify defects, measure components, and verify assembly steps.

At ALPHR, we take this one step further. We do not simply drop a camera onto a line and call it a day. We design vision inspection systems that fit seamlessly into our customers existing processes. We consider everything from environmental lighting to cycle time and operator feedback. Because when a system is properly designed, it does not slow production down, it makes it flow.

Our experience spans from simple part-present checks to complex display testing for LCDs, TFTs, and OLEDs. These systems can detect pixel flaws, verify colours, check contrast and brightness, and confirm that every display is performing exactly as it should. Whether it’s verifying that a DUT’s display shows the right warning at the right time or ensuring a screen lights up correctly, we make sure every detail is flawless.

The difference data makes

Another reason vision inspection is such a powerful problem solver is the data it produces. Every inspection generates valuable information that tells a story about the health of your production process. Patterns emerge. Trends become clear. Small shifts in measurements that might have gone unnoticed can be spotted early and corrected before they affect quality.

At ALPHR, we do not just hand over data; we turn it into insight. Our systems collect, organise, and present information in a way that actually helps teams make better decisions. The result is not only improved quality control but also a stronger, smarter production process that grows more efficient over time.

Building trust through consistency

When a manufacturer introduces vision inspection, something interesting happens. Teams begin to trust the process more. Quality control stops being reactive and becomes proactive. People no longer spend time arguing about what went wrong; they work together to make sure it does not happen again.

Consistency builds confidence. Confidence builds trust. And trust allows everyone, from operators to managers to customers, to sleep a little easier at night knowing that the technology is quietly doing its job in the background.

The quiet revolution on the factory floor

Vision inspection might not be the loudest part of your production line, but it is often the most valuable. It does not just check parts; it protects reputations. It reduces waste, saves energy, and helps businesses achieve the level of quality that today’s customers expect as standard.

At ALPHR, we like to think of it as the quiet revolution in modern manufacturing, one that keeps your line moving, your customers happy, and your team confident in every product that leaves your factory.

Sometimes, the best problem solvers are the ones you barely notice. Vision inspection is one of them. Whether you’re testing an electronic module, a display panel, or a sensor housing, this technology gives you the edge you need. And once it becomes part of your process, you will wonder how you ever lived without it.