ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

ALPHR Modular Solutions

Modular Automation Solutions

Did you know that ALPHR are not only experts in the design and manufacture of special purpose machines but also offer a broad range of modular, standardised machines. ALPHR understands that market trends have changed and to accommodate this, so too has our offering. The needs of our clients have changed, requiring business to be more agile, adapting to challenges in supply chain, labour shortages and the redistribution of skilled labour.

Modular Automation Systems

Cost-effectiveness

Familiarity

Quicker ROI

Shorter lead-times

Well defined, proven solution

Off the shelf (OTS) spares

Defined foot-print

This offers benefits around greater job satisfaction, better value from staff and a safer working environment.

Automated Production

Increased availability and reduced unplanned downtime. Redeployment of skilled resources to higher-value tasks. Improved mean time between failures (MTBF). For current technologies used in control systems, these are in the range of 50-150 years. Lower cost of manufacture to gain a competitive edge.

Why Choose Bespoke Automation?

We can work with you to create your own Roadmap to Automation.

We can help you identify your automation goals.

We can help you realise your automation goals.

We can be your trusted implementation partner.

We will be there with continued support and advice.

Our specialist areas include:

Vision inspection/sensing and measurement

PLC, PC, and hybrid control systems

LabView/VB.Net software platforms

Rotary indexing machines

Interchangeable tooling

Laser marking solutions

Automated soldering

Automated screwdriver systems

Ultrasonic/laser welding

Integrated dispensing systems including adhesive, sealant and potting compounds

Palletised production lines

Leak detection/flow measurement

Robotics

Pulse staking

Hot and cold insertion, including induction heating

Plasma treatment

Our experience and collaborative methodology enable us to design and build systems to meet our clients’ requirements for automated production lines.

Please do contact us to find out more about how ALPHR can help. Our technology and industrial automation systems are available across the UK and globally.

The ALPHR Modular Workstations

The ALPHR Standard Laser Marking

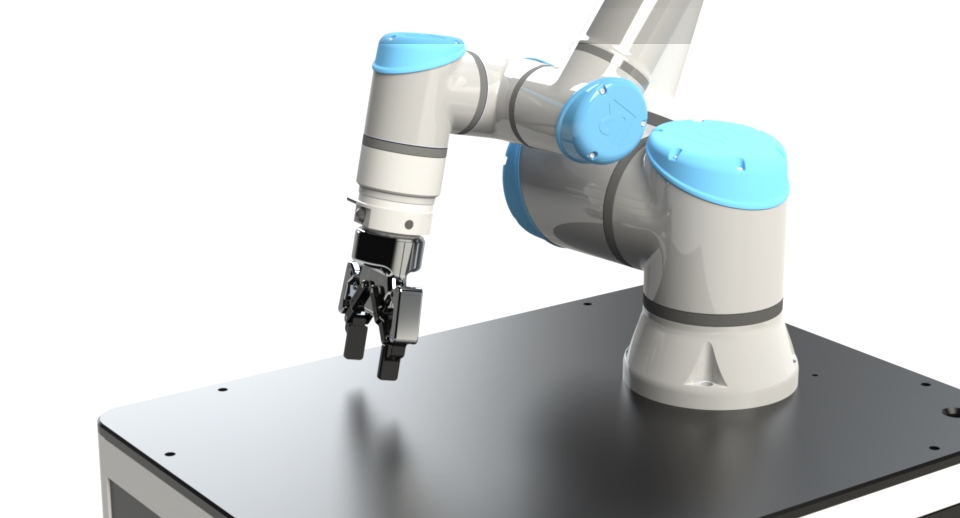

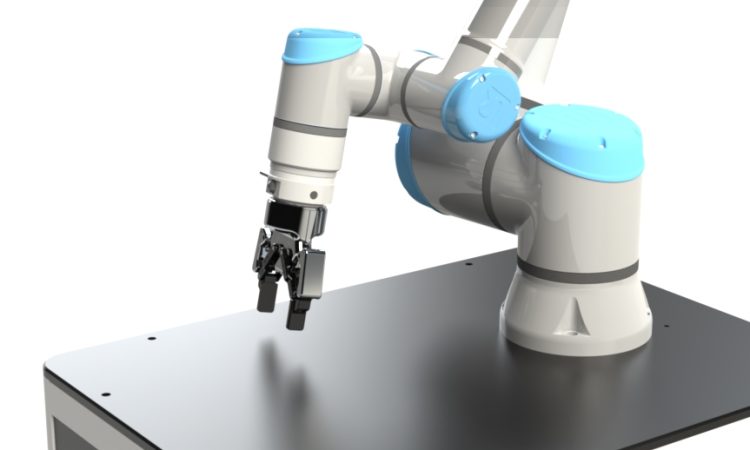

The ALPHR Standard Cobot Solution

ALPHR Flexi-Pod

Frequently Asked Questions

What is modular automation?

Modular automation refers to flexible, pre-engineered systems built from standardised components that can be easily configured or reconfigured to meet changing production needs. ALPHR’s modular stations are designed for fast integration, consistent performance, and adaptability across different applications.

What industries benefit most from modular automation?

Industries with evolving product lines or high-mix/low-volume production benefit most from modular automation. This includes:

- Automotive

- Medical Devices

- Electronics

- HVAC

- Aerospace

- Transportation

Modular automation allows these industries to scale quickly, reduce downtime, and adapt to market demands without redesigning entire systems.

How does modular automation improve ROI?

By reducing lead times, simplifying operator training, and enabling quicker reconfiguration, modular automation lowers upfront costs and accelerates return on investment. ALPHR’s standardised architecture also means spare parts and support are readily available, reducing maintenance costs and increasing system uptime.

Can modular automation be customised?

Yes. While modular systems are based on standard platforms, ALPHR offers flexible configurations and custom tool integration. This allows businesses to combine the speed and cost-efficiency of standardisation with the benefits of tailored automation.

Is modular automation suitable for future upgrades?

Absolutely. One of the key advantages of modular automation is its scalability. ALPHR’s systems are designed to accommodate new components, products, or processes, ensuring long-term usability and future-proofing your investment.