When you’re trying to improve efficiency on the shop floor, it’s often the little things that get overlooked.

Manually entering test results. Loading and unloading parts into a test station by hand. Tapping keys. Moving trays. Scanning barcodes. Clicking “Next.”

None of these tasks make the product any better. They don’t improve quality. They don’t boost customer satisfaction. And yet, they eat up time, introduce opportunities for error, and add cost to every unit you produce.

We help manufacturers identify and remove these non-value added steps, because real efficiency means spending time on what actually moves the needle.

What Are Non-Value Added Steps, Really?

Not every action on the production line adds value. In fact, many tasks, especially in manual or semi-automated setups, exist just to keep the process running, not to enhance the product itself.

Here are two of the most common offenders:

- Manual data entry: Operators recording test results by hand or typing them into a terminal. This is time-consuming and prone to mistakes, especially under pressure.

- Manual loading and unloading of test stations: Repetitive tasks that not only slow down cycle time but also tie up skilled operators who could be adding value elsewhere.

These actions may feel like part of the process, but they don’t directly contribute to product quality or performance. And in a high-volume environment, they quickly become bottlenecks.

Why These Steps Hurt More Than You Think

It might only take a few seconds to log a test result or load a part. But multiply that across every unit, every shift, and every station and suddenly you’re looking at hours of lost productivity per day.

Not to mention:

- Higher labour costs – You’re paying skilled operators to do tasks a machine could easily handle.

- Increased error risk – Manual data entry is one of the most common sources of production errors and reporting issues.

- Slower cycle times – Even minor delays at one station can ripple downstream, reducing overall throughput.

- Inconsistent results – Human variation in timing and positioning affects repeatability and performance.

If you’re tracking OEE, these non-value added steps are likely dragging down your efficiency and availability scores without you even realising it.

Automation Removes the Waste

The good news is, automation is perfectly suited to eliminate these unnecessary steps, freeing up your team to focus on what really matters.

Our automation solutions are designed to remove repetitive, low-value tasks from your process, and replace them with systems that improve speed, accuracy, and reliability.

Let’s take a closer look:

- Automated Test Result Logging

Instead of relying on manual entry, ALPHR systems automatically capture, record, and store test data in real time.

Our platforms integrate with your MES or production database to ensure every result is traceable, timestamped, and error-free. No more typing errors. No more missing data. Just clean, reliable records that are ready when you need them.

- Hands-Free Loading and Unloading

Manual part handling might seem harmless, but it’s a major contributor to inconsistent cycle times and operator fatigue. ALPHR test stations can be designed with automated loading/unloading systems, including:

- Servo-driven part trays

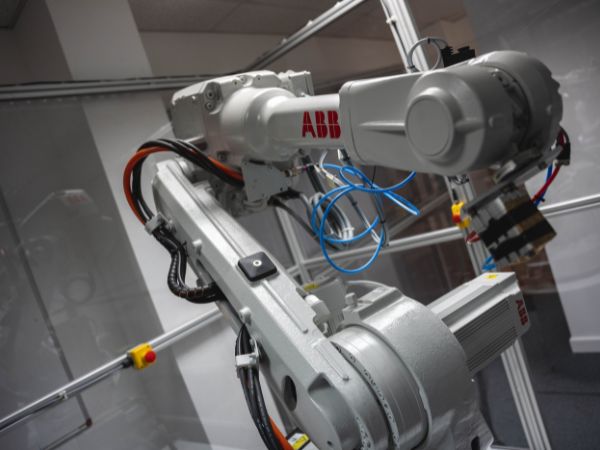

- Robotic arms or cobots

- Guided part placement systems

- Conveyor-fed integration

These solutions don’t just speed up the process, they reduce the risk of incorrect loading, ensure consistent orientation, and improve repeatability at every stage.

- Operator Efficiency Gains

By automating the admin and the heavy lifting, you give your operators the chance to focus on value-added activities—like quality checks, troubleshooting, or continuous improvement.

This shift doesn’t just make your line more efficient, it makes your workforce more engaged and effective too.

- Integrated Systems That Work Together

We don’t believe in adding automation for the sake of it. Every ALPHR system is built to fit into your existing line, with standardised software, modular design, and global support.

That means:

- Seamless integration with your existing databases

- Fewer manual interventions between processes

- Greater consistency across shifts and sites

- Scalable upgrades when your process evolves

A Smarter Way to Build a Smarter Factory

Reducing waste is one of the first steps toward a leaner, more productive operation. And eliminating non-value added tasks is often one of the fastest wins.

We work with customers across automotive, electronics, and industrial sectors to streamline their testing and assembly processes, replacing manual handling and data entry with automation that makes a measurable difference.

Let’s Remove the Tasks That Don’t Add Value

If you’re spending time on steps that don’t improve your product, it’s time to take a closer look at what automation can do.

At ALPHR, we help you streamline, standardise, and scale, by cutting out the noise and focusing on what truly matters to your operation.

Talk to us today to explore how we can help you remove non-value added steps from your line.