Are tooling changeovers eating up more time than they should? If your team is regularly stopping production to swap out insertion heads, adjust fixtures, or recalibrate between product variants, you’re not alone. It’s a common bottleneck that often gets brushed off as just part of the process. But over time, these stop-start moments add up. They slow down output, put pressure on teams, and can quietly drain both productivity and profit from your line.

Let’s talk about a better way to approach it.

The Hidden Cost of “It’s Just a Changeover”

You’ve likely heard it before on the shop floor.

“It’s just a quick changeover. We’ll be back up in ten minutes.”

Except it’s rarely just ten minutes. It’s ten minutes to swap the tooling. Another ten to recalibrate. A test run or two to check alignment. And then a few more minutes while someone troubleshoots the inevitable issue.

Before you know it, 30 or 40 minutes have passed. Multiply that by several changeovers a day, across multiple shifts, and the time lost becomes impossible to ignore.

And when you’re dealing with something as precise as stepper motor insertion, any misalignment during changeover introduces risk. Even a small error can impact product quality or lead to rework.

The Problem With Traditional Insertion Setups

Most insertion systems were originally built to handle a small number of products. That might have worked in the past when production was stable and product lines didn’t change often.

Today, things are different. Customers demand more variety. Product designs evolve faster. Production teams need to be flexible, not locked into rigid setups.

If your system can only handle one or two variants without manual adjustments, you’re falling behind. Every new product variant becomes a burden. Each one requires extra time, more training, and increased potential for mistakes.

There’s a Smarter Way to Handle Changeovers

The question to ask is this. What if your insertion system could switch between multiple product variants with minimal downtime?

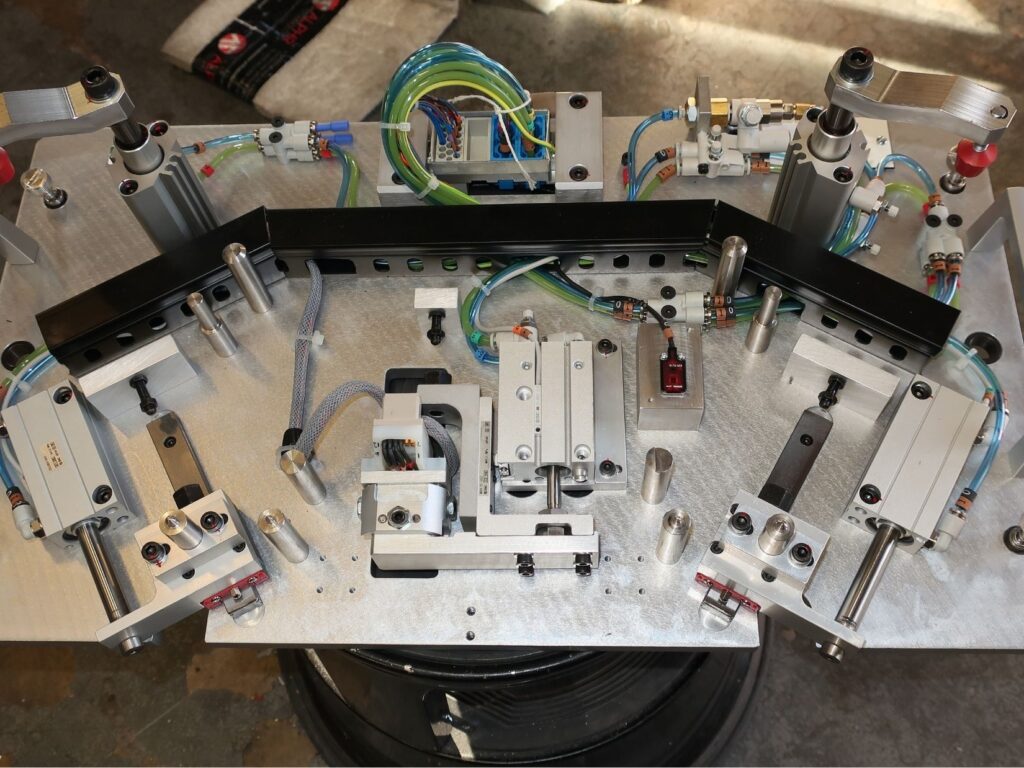

That’s the goal behind interchangeable tooling and modular insertion heads. With this approach, operators can switch setups quickly using quick-release mechanisms or pre-calibrated parts. In some systems, the changeover process is automated or tool-free altogether.

This dramatically reduces downtime and makes it easier to maintain consistency across different builds. It also helps teams respond faster to changes in production demands without the usual delays.

More importantly, it means your system can evolve alongside your product range.

Flexibility is a Long-Term Advantage

The value of a flexible insertion system is not just in saving time today. It is about building a more agile, scalable production environment that is ready for tomorrow.

Think about how often your production needs have shifted in the past year. New product specs. Small batch runs. Engineering tweaks. It is happening more frequently than ever.

With a rigid setup, each change becomes a challenge. With a flexible one, it is just another part of the workflow.

Modular tooling, standardised fixtures, and automated changeovers let you adapt without the usual stress. That means fewer delays, better output, and a system that continues to deliver value no matter what comes next.

Real Stories From the Factory Floor

We worked with a manufacturer who was dealing with frequent changeovers between just two product types. Each switch took over 30 minutes. It seemed minor at first, but across a week, it added up to hours of lost production.

By introducing a modular insertion head and interchangeable fixtures, the team cut changeover time down to less than five minutes. Not only did they save time, but they also gained the confidence to add two new product variants to the line without any additional equipment.

Sometimes solving a big problem starts with fixing something small.

Why Smarter Insertion Systems Save More Than Just Time

Tooling changeovers may seem like a necessary inconvenience, but in reality, they are often a sign that your system is working harder than it needs to. With the right approach to stepper motor insertion, you can reduce downtime, improve consistency, and gain the flexibility your production line needs to stay competitive.

At ALPHR, we build insertion systems with adaptability in mind. Whether you’re dealing with multiple product variants or looking to future-proof your line, we can help you design a smarter solution that works for you now and in the long run.