ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

End of Line Testing Automation

End of Line Testing Automation for Reliable Automotive Production

ALPHR Technology is proud to offer standard and special-purpose solutions to assemble and test a wide range of products for a variety of industry sectors. We have years of experience in End of Line Testing, supported by a team of dedicated engineers and directors to provide solutions to fit your business needs perfectly.

Bespoke Solutions

End of Line Testing is a critical process for many manufacturers, reducing errors and defects and improving the quality of products and services. ALPHR offers flexible, scalable assembly and testing solutions for many electronic products, including:

Control boxes

Instrument clusters

On Board Charging units (OBC)

Battery Monitoring Systems (BMS)

Battery testing

Motors and Inverters

PWM control valves

Solenoid valves

Rail network relays

In-car entertainment systems

Through constant development and innovation, ALPHR’s control platform provides industry leading data collection, product communication, traceability, and the creation of results algorithms, providing comprehensive, real-time analysis, enabling our customers to make informed, data-driven decisions.

By working closely with our customers to fully understand their specific requirements, ALPHR can provide End of Line Test solutions across a broad spectrum of testing processes, including:

PWM signal control

Current measurement

Voltage measurement

Frequency measurement

Leak and Flow testing

Programmable AC voltage control

Programmable DC voltage control

Bi-directional communication with various products

Resistance measurement

Speed of switching in relays

Drop-in and drop-out voltage/currents

Hysteresis measurements and calculation

Automated End of Line (EOL) testing plays a vital role in ensuring product reliability, safety, and performance. ALPHR’s systems help manufacturers achieve consistent results while improving efficiency across production lines.

Key Benefits:

- Improved Quality – Detects faults early to prevent defective units from leaving the line.

- Reduced Costs – Minimises scrap, rework, and warranty claims through reliable fault detection.

- Higher Throughput – Speeds up the testing process compared to manual inspection.

- Data-Driven Decisions – Real-time data collection enables continuous process improvement.

- Repeatability Across Sites – Standardised test systems ensure consistent results globally.

By investing in automated EOL testing, manufacturers gain tighter control over quality, reduce production risks, and build greater confidence in every product shipped.

If you have any questions about our electrical testing solutions, don’t hesitate to get in touch with ALPHR Technology today. Our team of experienced engineers is readily available to assist with any queries or provide detailed information, whether you’re located in the UK or anywhere else around the world. We take pride in offering prompt, reliable support and are committed to helping you find the right solutions to meet your specific needs.

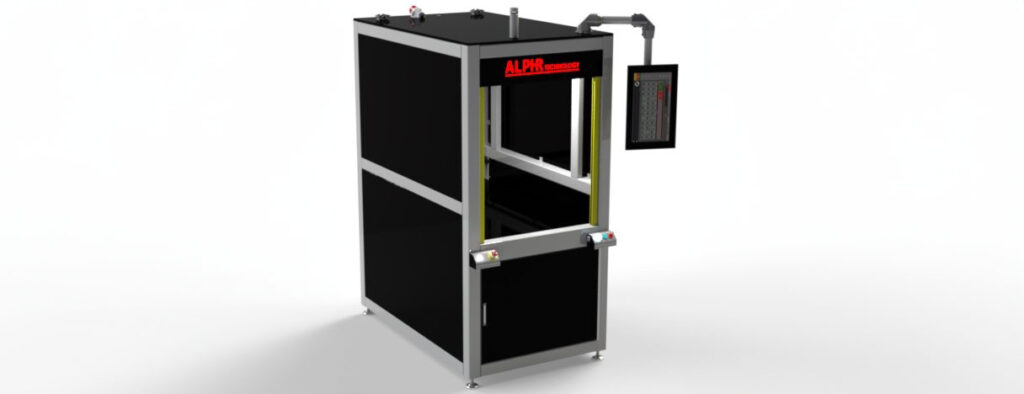

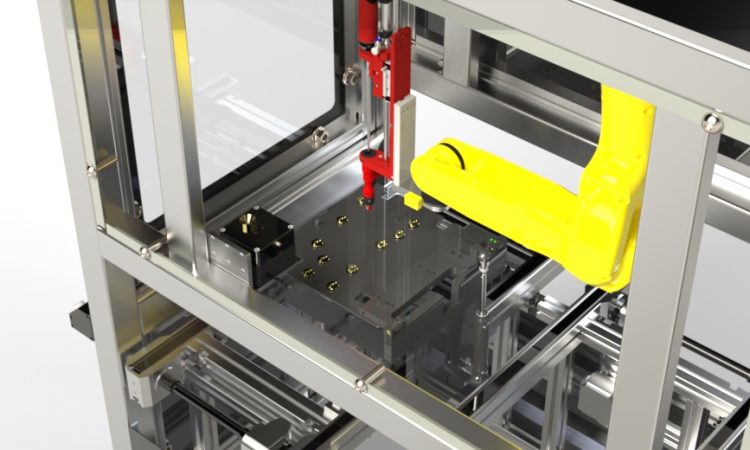

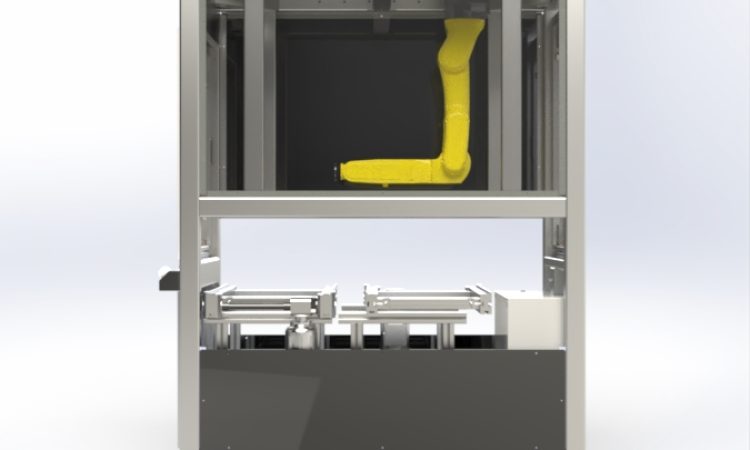

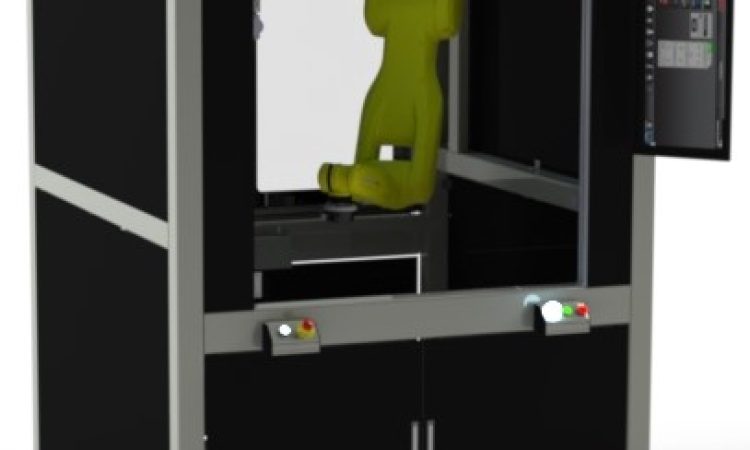

Flexi Pod Automation

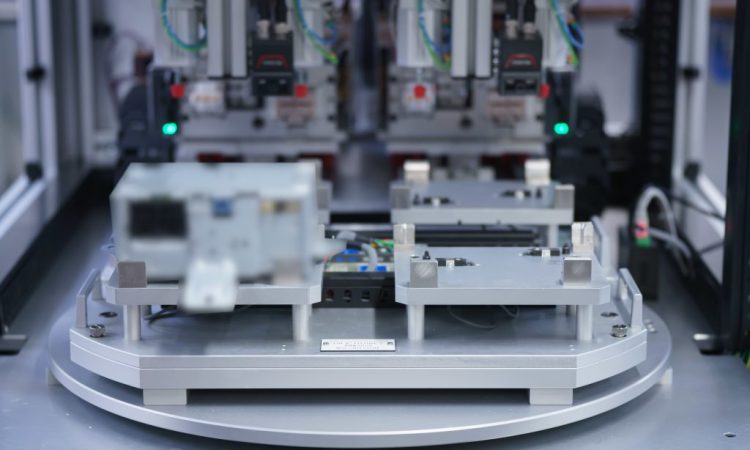

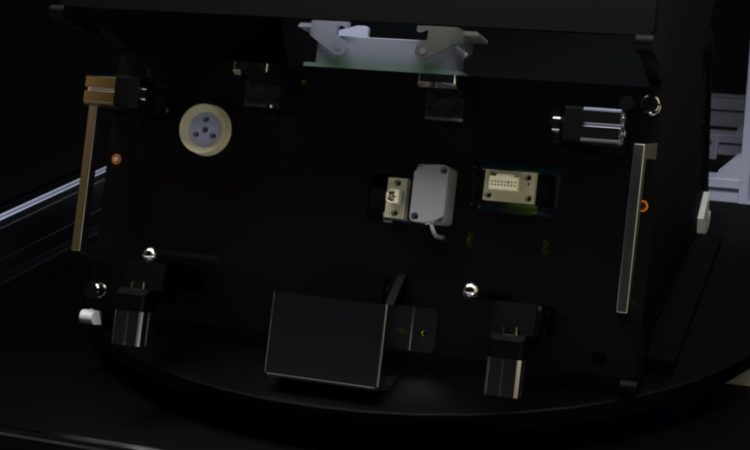

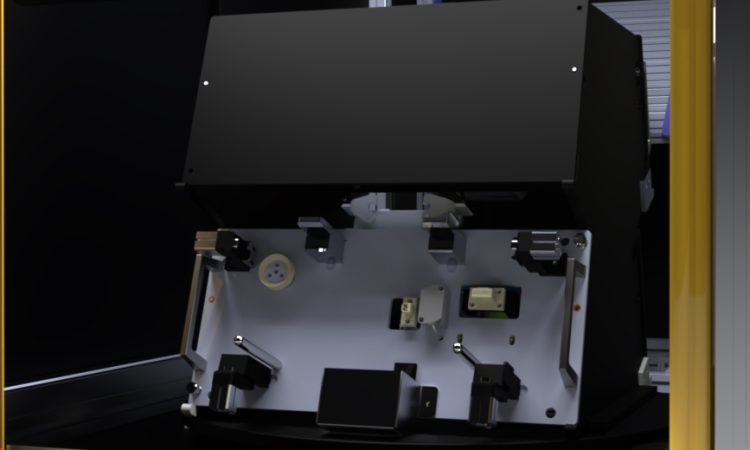

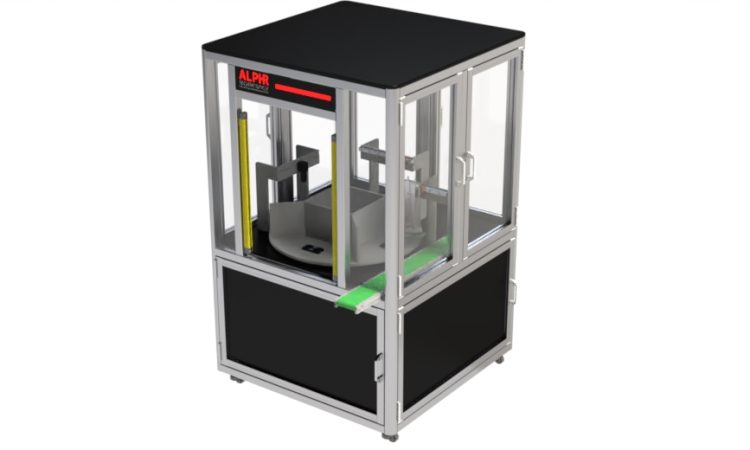

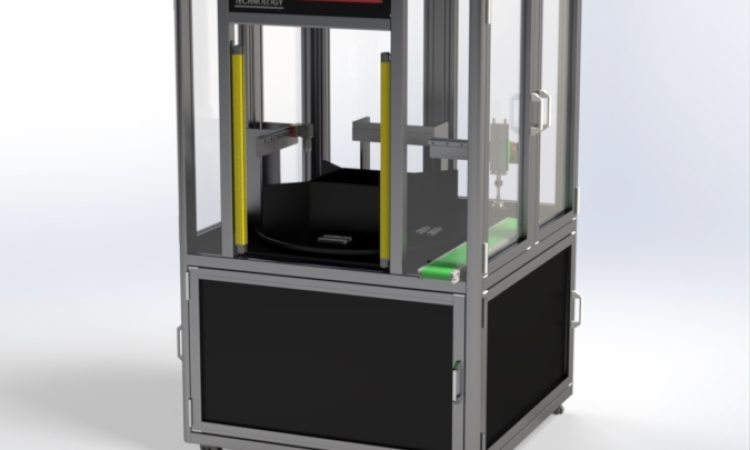

Designed to support modern production processes requiring robots, palletised assembly or rotary indexing tables, the Flexi-Pod utilises standard frames, and controls architecture to create a flexible, modular platform.

The Flexi-Pod can be supplied in a single or multi-station configuration, enabling a wide range of processes to be accommodated on a single platform, including automatic screwdriving, dispensing, laser marking, vision inspection, End-of-Line testing, pick & place, leak/flow testing, and assembly.

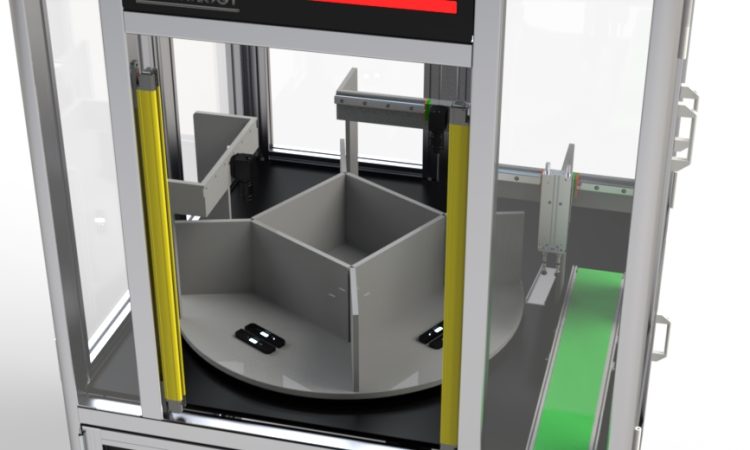

With a welded structure, the Flexi-Pod is designed to support up to two robots working simultaneously or up to a four-station rotary table.

The flexible, modular design allows additional stations to be easily added as production demands increase. Changes to tooling can be quickly implemented to accommodate new variants or changes to existing products.

Our Production Flexi-Pod Range

Shorter lead times, ease of maintenance, improved serviceability, reduced spares, quicker factory implementation, and a more cost-effective solution resulting in a quicker ROI are just some the benefits available with the Flexi-Pod.

Standard Flexi-Pods:

1000mm (W) x 1600mm (D)

Options include:

Monitor arm

SCADA HMI

Light guard or safety door

Centralised PLC control system for multiple stations, or individual PLC control system

Infeed/outfeed conveyor, 2 or 4 station rotary or operator workstation

No robot, one robot or twin robot